Rotomag™ X22

Versatility and Dependability

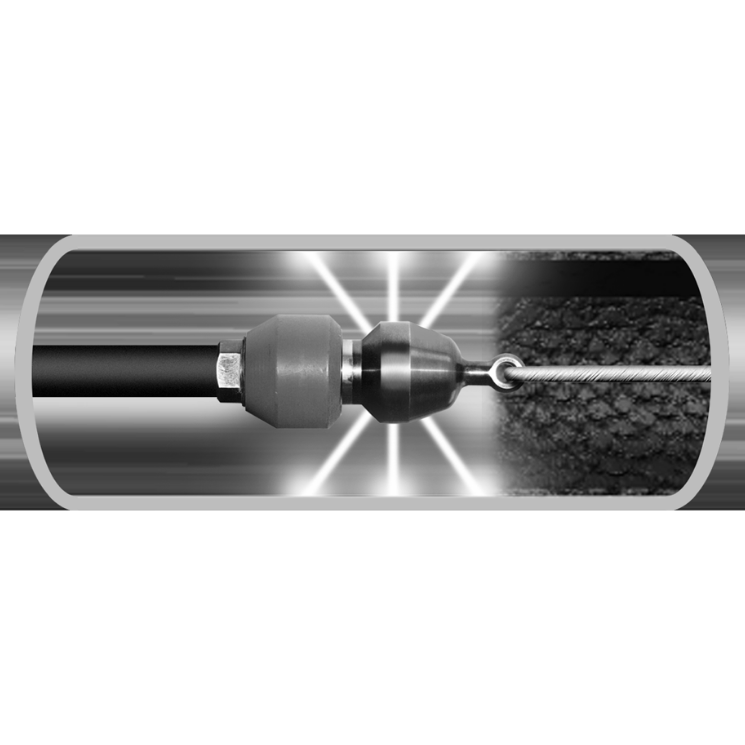

The Jetstream RotoMag™ X22 and X22N are 2-D self-powered rotating tools designed for cleaning stacks, sewer lines, drains, tanks, on-line boilers, and other large diameter pipes. Spinning on a film of high pressure water using Jetstream water bearing technology, the tool has no bearings to fail or oil reservoirs to maintain, keeping service simple and fast. Using a maintenance free magnetic braking system moderates the rotational speed of the tool, while eliminating the need for lubricating oils or friction plates for ease of use. With a total of 8 nozzle ports the RotoMag™ X22 can be configured in a variety of patterns to operate at 22,000 psi or 15,000 psi with an adapter to achieve optimum flow and rotation speed for every job.

Manuals And Docs

For more information, browse our helpful literature to better understand the functionality of your equipment.

RotoMag™ X22 Product Instruction

RotoMag™ X22 Quick Start Guide

Key Specs

- Maximum operating pressure 22,000 psi (1517 bar)

- Maximum flow rate 80 gpm (303 lpm)

- 3/4″ MP Female inlet connection

- Clean pipes ranging from 3.5 inches (8.89 cm) to 60 inches (152 cm) in diameter.

- Rotation speed from 50 to 300 rpm

- RotoMag™ X22 (1/2″ – 28 UNEF ports) uses Tungsten Carbide RM Series nozzles, Sapphire RMS Series nozzles, or Synthetic Diamond RMD Series nozzles

- RotoMag™ X22N (1/4″ NPT ports) uses Tungsten Carbide P4TC Series or steel JS4F or JS4FD nozzles.

- Assembled weight 6 lbs (2.7 kg)

Key Features

- Maintenance free magnetic braking system controls rotational speed.

- 5 minute replacement of wear components in the field with Rebuild kits using only two standard hex wrenches.

- Oil and lubricant free.

- 8 nozzle ports with many possible configurations.

- Accessories such as tow rings, centralizers and extension arms available.